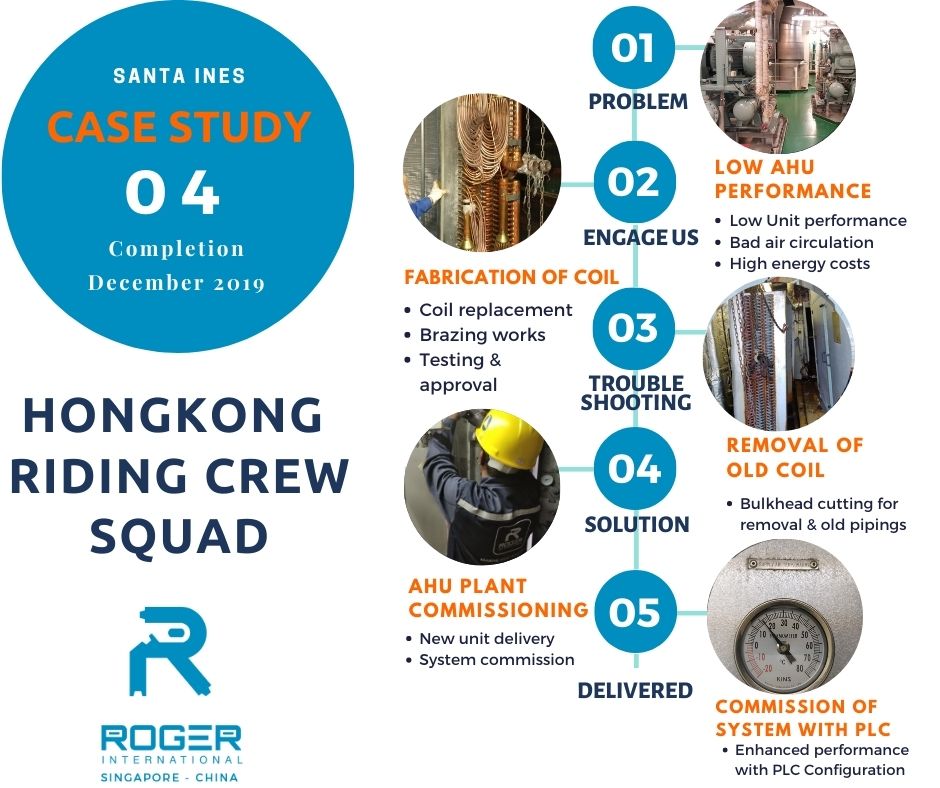

VESSEL DETAILS

Name : Santa Ines

Type: Container Ship

Construction year : 2012

IMO: 9444845

Carrying Capacity: 7114 TEU

LOA: 299.9 m

Width: 42.92m

Service Location: Hongkong Riding Crew Squad, Hongkong

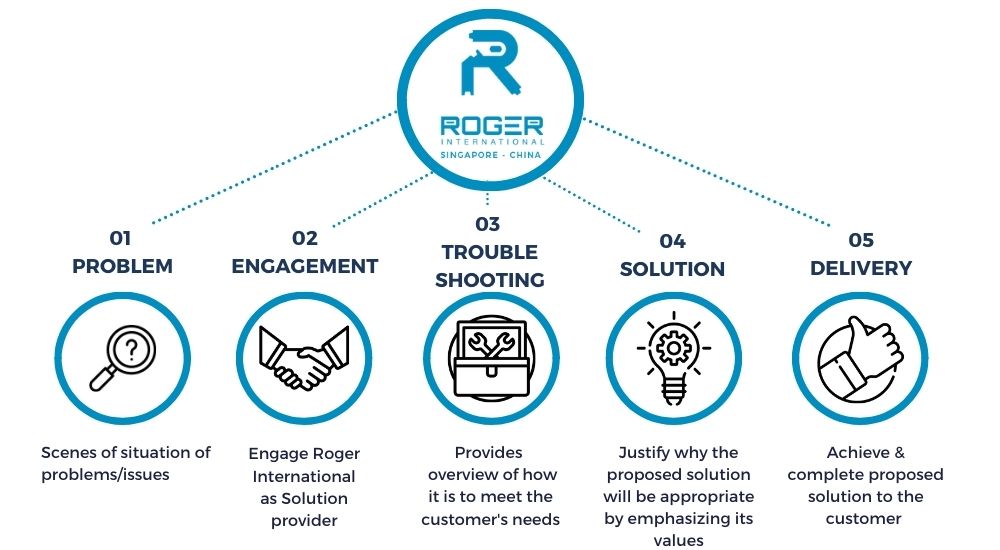

As per OUR 5-STEPS FORMULATION..

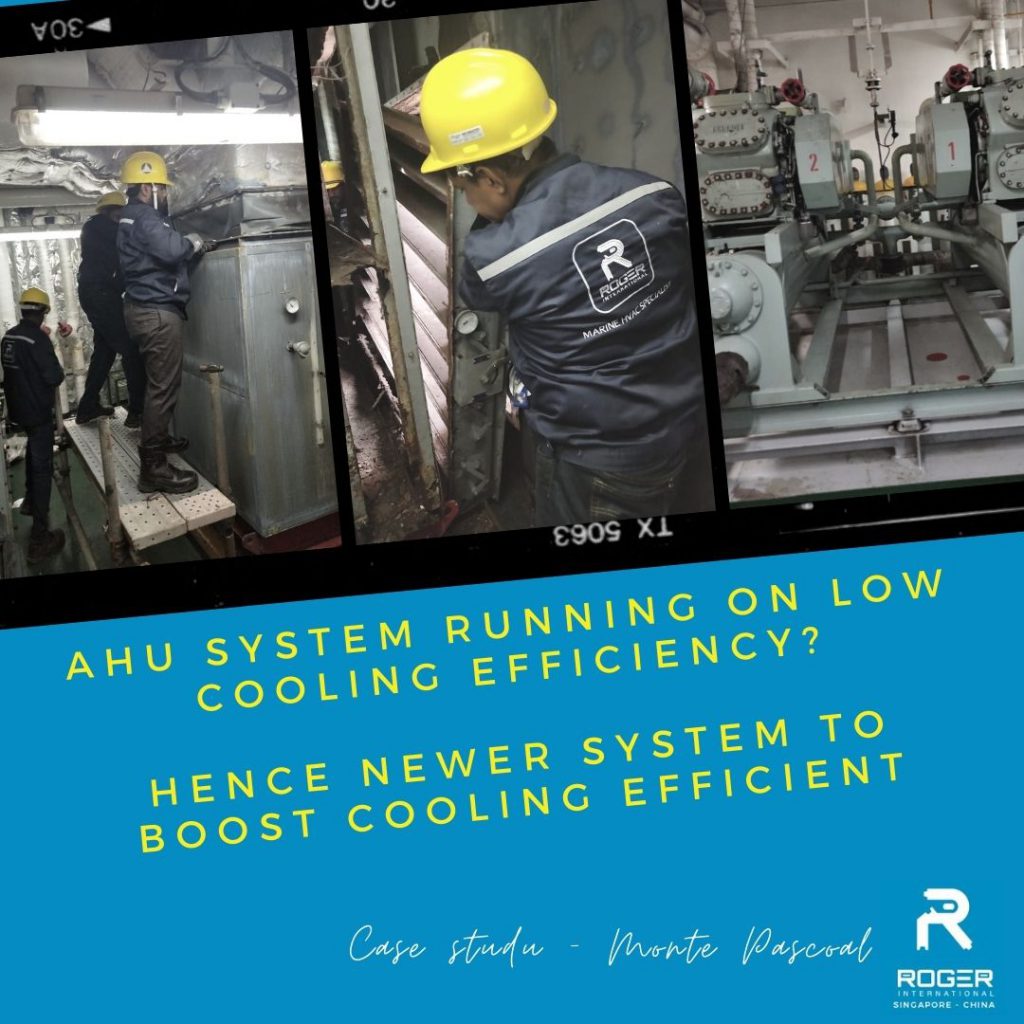

The Problems & Concerns;

- Low AHU Performance

- Fabrication of new evaporator coil

- Removal of old coil

- Commissioning of AHU plant

- Configuration of PLC

The Findings & Solution:

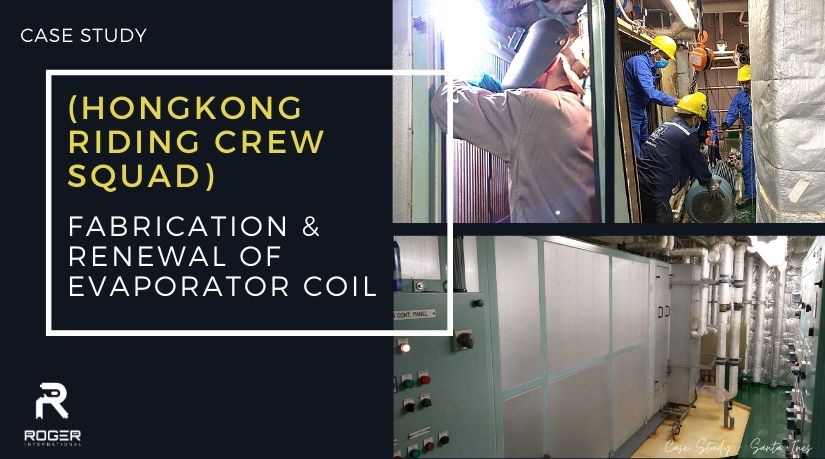

We replaced the old evaporator coil, our team of engineers had to temporary cut the bulkhead to remove the equipment.

After all operations were conducted, testing deemed the new installations fully functional.

Most importantly, the installation process was completed by our Hongkong Riding Crew in Hongkong.

The scenario..

This was a AHU evaporator coil removal and installation operation. As reported by the ship manager, the coil was showing signs of usage after extensive working hours. We engaged ourselves to provide our client with AHU installation & commissioning services.

Due to the size of the evaporator coil, our team of engineers had to temporary cut the bulkhead to remove the equipment. After all operations were conducted, testing deemed the new installations fully functional.

This operation was conducted by our Hongkong Riding Crew in 2 different ports in Hongkong

featuring our riding crew in hongkong

conducting hvac services onboard the vessel

what you need to know

As you know, Roger International has considerable experience in the maintenance, repair & installation of heating, ventilation and air conditioning systems on board ships.

riding crew conducting hvac services

In this case study, all the operations were performed by our team of technicians and engineers as riding crew. Because flexibility and time are important to our clients, we will adapt to all your constraints and fulfill our mission accordingly.

We are not only able to serve ports, anchorages and shipyards in China, Singapore and Europe, but we are also able to operate as riding crews all over the world.

P.S. : Note that all our engineers are tested and covid free during this pandemic period.

what you need to know about

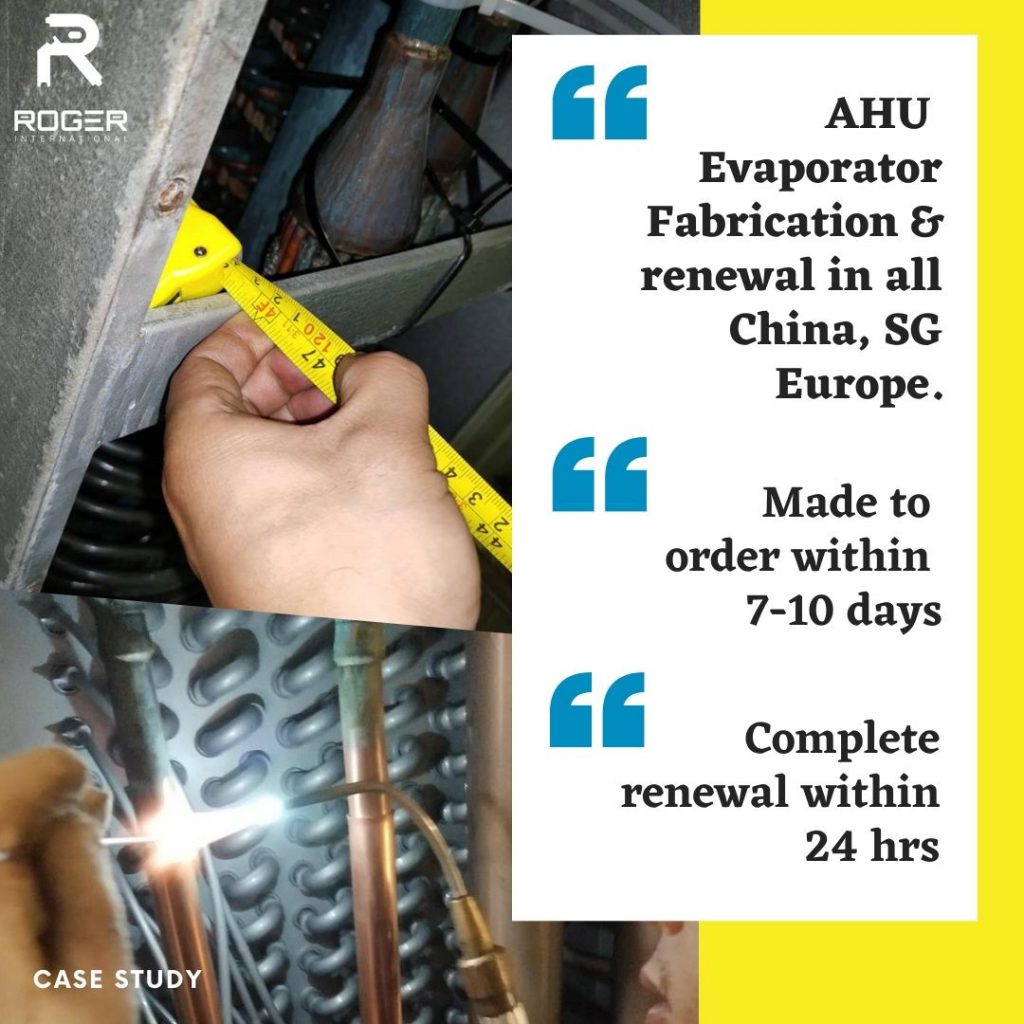

Evaporator coil fabrication and installation

evaporator coil fabrication

At Roger International, we can perform the customization and manufacturing of your future evaporator coil in 7 days guaranteed! Whatever the size or requirements, we are able to provide adapted and appropriate equipment for optimal and long-lasting performance. We are able to serve all shipyards, anchorages and ports in China.

evaporator coil installation

The installation of evaporation coils is one of the things we do best among our wide range of installation services. With nearly 20 years of experience, we guarantee that your new unit will be installed by our field men in less than 24 hours!

P.S. : Note that all our workers are tested and covid free.

similar cases:

Related case study

Service: AHU Evaporator Coil Fabrication and Renewal Scope

Vessel: Maersk Lirquen

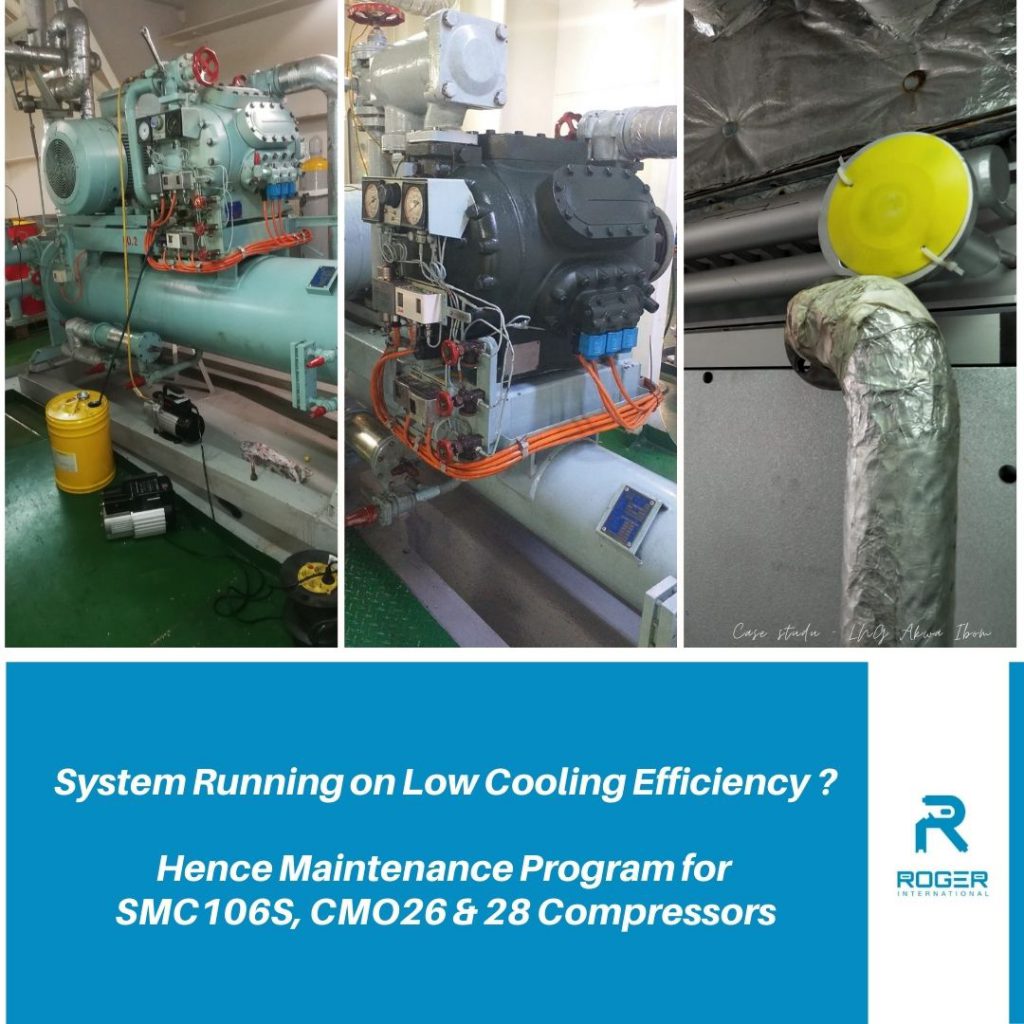

Related case study

Service: Maintenance Program for SMC106S, CMO26 & 28 Compressors

Vessel: LNG AKWA IBOM

Want to find out more about the services involved in this Case Study?

For more information on the process of the services involved, click on the button below to download our FREE Case Study PDF version.

RELATED BLOG ARTICLES

BOOK NOW FOR A FREE INSPECTION + GET 10% OFF OUR SERVICES

To eligible for a FREE inspection, all you have to do is to fill up the form below today.

Should u require any parts change or repair works done, we are pleased to inform that we will be extending a 10% off to you if you use the form below.

We are here to resolve any issues that you might be facing and to stay fully committed to supporting you and your crew throughout these challenging times.