VESSEL DETAILS

Name : Rio Bravo

Type: Container Ship

Construction year : 2009

IMO: 9348091

Carrying Capacity: 5905 TEU

LOA: 286.45m

Width: 40.6m

Service Location: PSA, Singapore

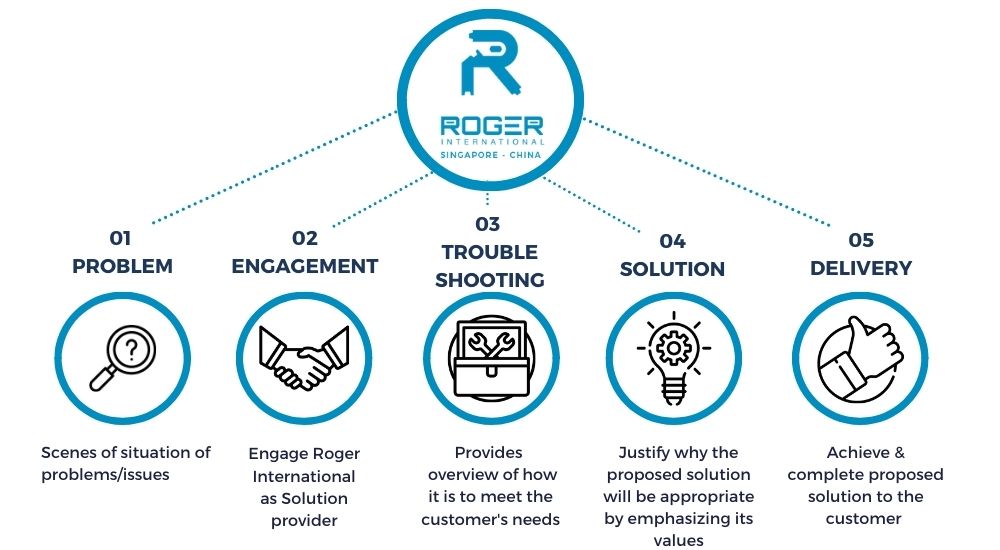

As per OUR 5-STEPS FORMULATION..

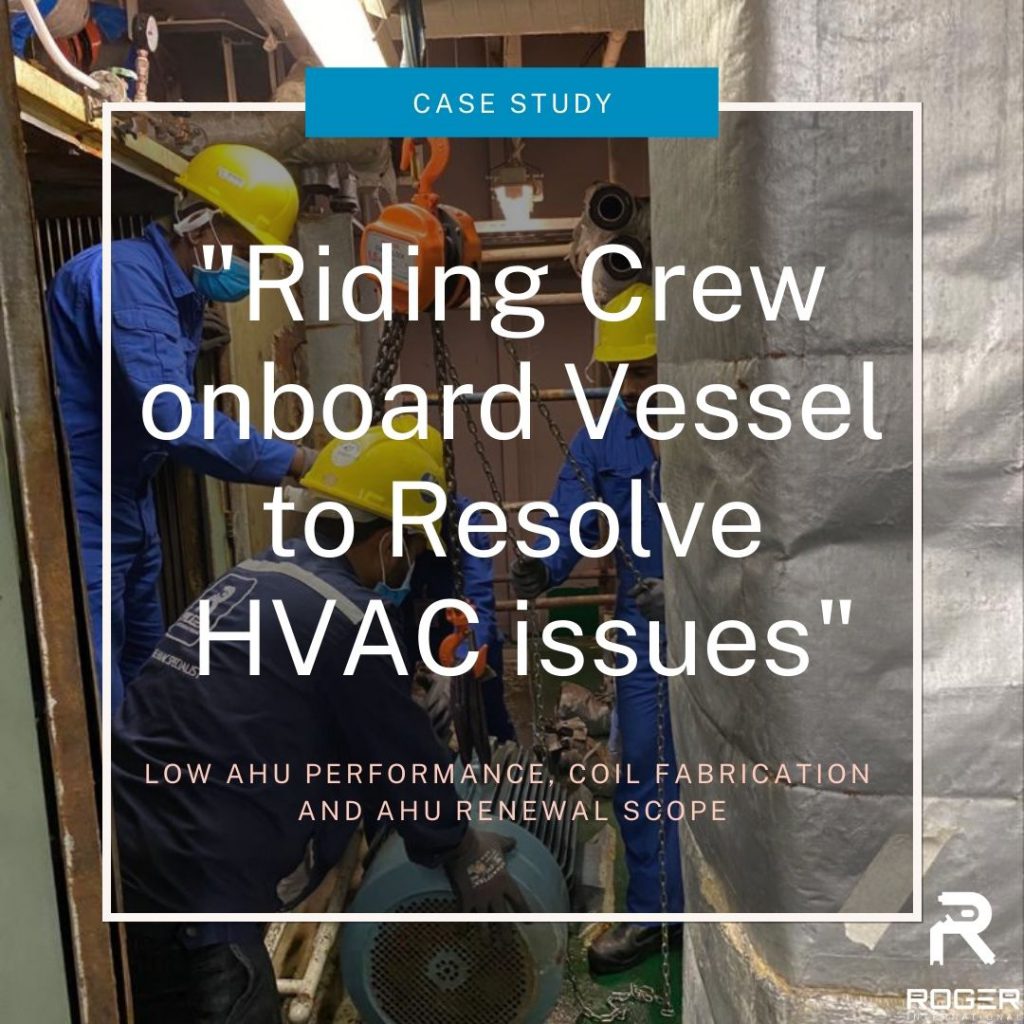

The Problems & Concerns;

- Low Main AC and Condenser performance

- Overhauling HVAC system

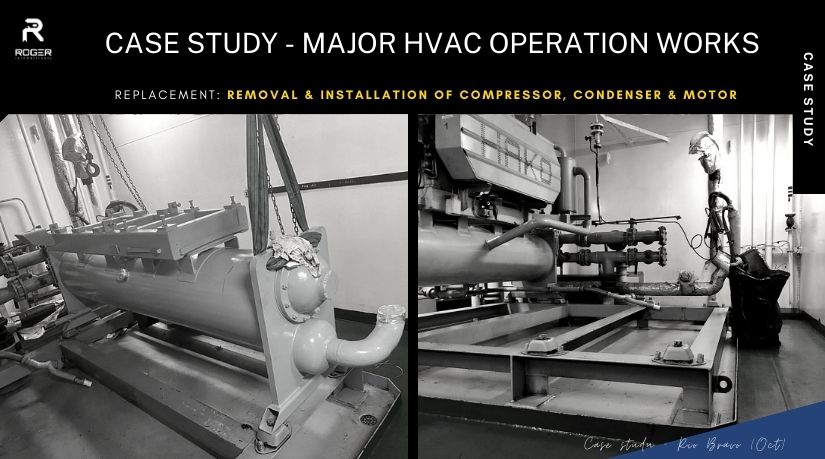

- Replacement of Condenser & AC

- Leak testing

- System renewed and commissioned

The Findings & Solution:

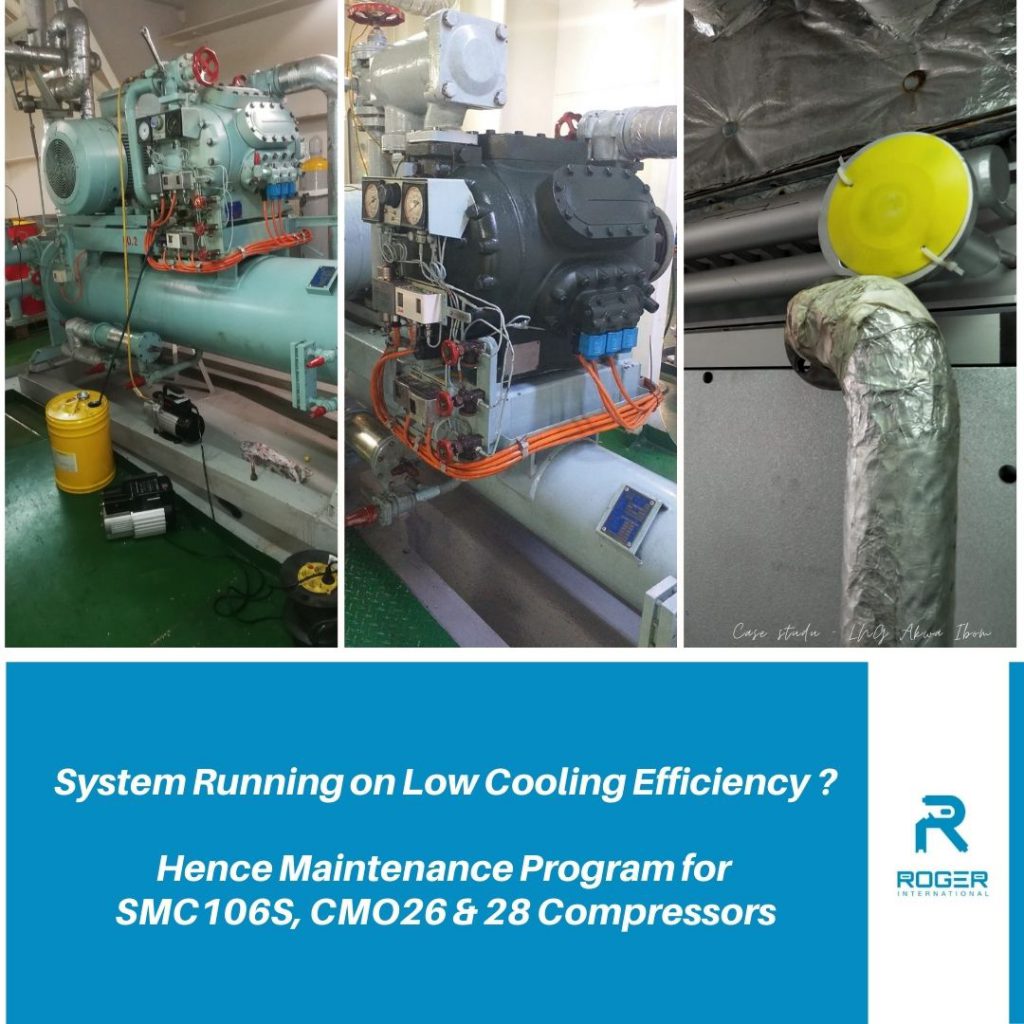

Main AC compressor SMC106S & Condenser of System #2 were disconnected & transported to our workshops for overhauling works & pressure testing respectively.

After successful overhaul, the Compressor, Condenser & motor are to be reinstalled in position.

The scenario..

It was found that HVAC System 2 compressor and condenser was causing low HVAC performance. Units suffered from extensive operating hours and overhauling services is highly recommended.

After dismantling the equipment, we send System 2 which includes both units directly to our workshops where our engineers conducted overhauling operations.

With our own developed overhauling process and techniques, the result has been proved to be efficient, fast and reliable. After all operations were conducted, our engineers reinstalled compressor, condenser & motor. Welding & brazing works were made to join the pipings.

A major operation of such scale is usually done in shipyards. However, with our special techniques and processes, the operations was done at a port by our engineers as 2 jobs in 2 separate calls.

A new suction liner filter core casing as well as 2 new liquid line solenoid valve were installed. Finally, the system was flushed using R141B gas & pressure tested using nitrogen. Leaks were spotted on the No.1 & 2 shared suction bypass vibration eliminator pipelines.

Main AC compressor SMC106S & condenser of HVAC System 2 were disconnected & transported to our workshops for overhauling works & pressure testing respectively.

After successful overhaul, System #2 Compressor, Condenser & motor are to be reinstalled in position.

featuring major hvac service operation on board

overhauling of system no 2 including condenser, compresser and motor

what you need to know

In one day, our team is able to safely dismantle massive units and transport them directly to our workshops. During the overhaul of your equipment, our onboard technicians perform maintenance operations on all connected units for optimal reinstallation.

Engineers in charge of system overhaul

After delivery of condenser and compresser units to our workshops, our engineers will directly perform all overhaul operations taking into account the number of hours your unit has been in operation.

Once this operation is completed, the HVAC equipment is returned to the site without delay and reinstalled, configured, commissioned and tested.

what you need to know about

how roger international manages Major hvac service operation efficiently

location of service

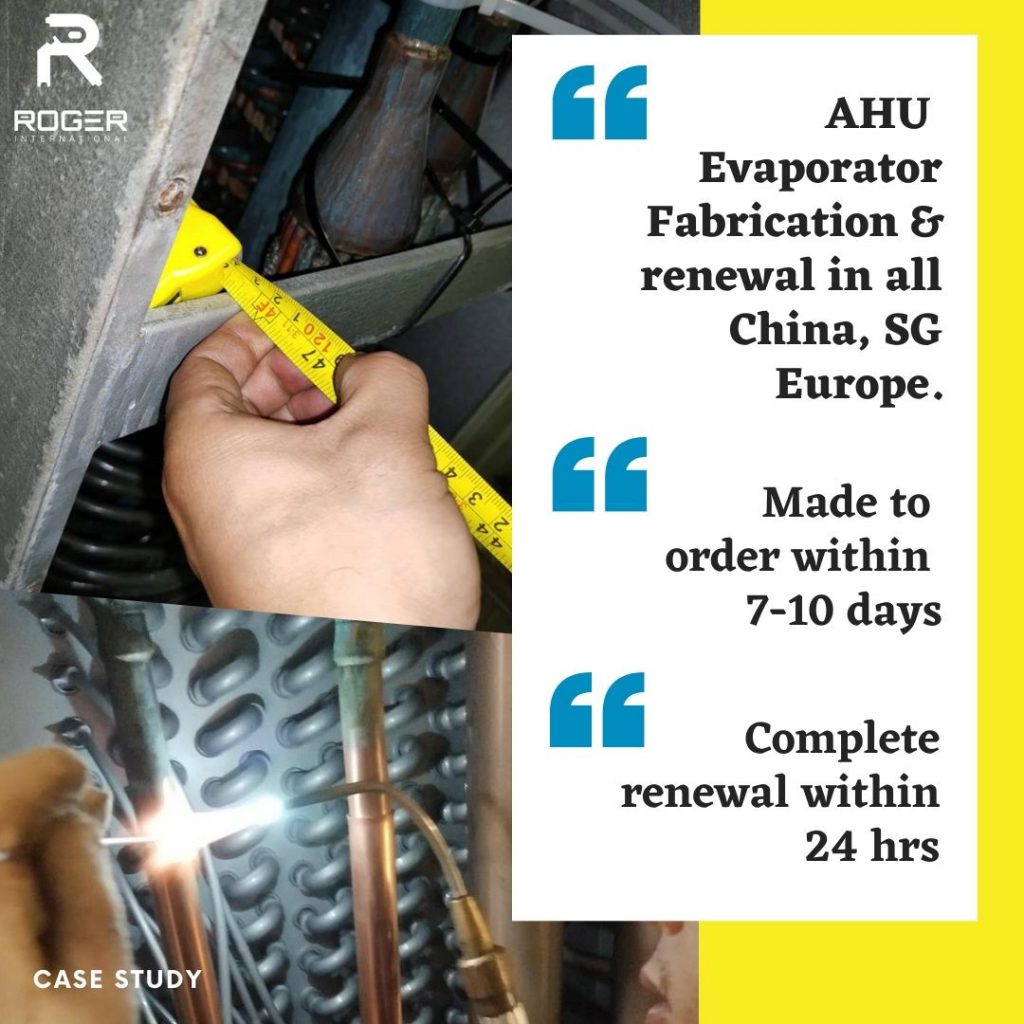

Our technicians and engineers serve all ports, shipyards and anchorages in China, Singapore and Europe in an optimized timeframe.

unique developed techniques

In addition to the rapid deployment of field personnel, Roger has developed a unique work process to carry out any major operation with reduced costs and time.

A major operation of such scale is usually done in shipyards. In this case study, and by implementing with our special techniques and processes, Roger International is able to complete the operations was split into 2 jobs and completed within 2 calls in ports instead.

other case studies:

Want to find out more about the services involved in this Case Study?

For more information on the process of the services involved, click on the button below to download our FREE Case Study PDF version.

RELATED BLOG ARTICLES

BOOK NOW FOR A FREE INSPECTION + GET 10% OFF OUR SERVICES

To eligible for a FREE inspection, all you have to do is to fill up the form below today.

Should u require any parts change or repair works done, we are pleased to inform that we will be extending a 10% off to you if you use the form below.

We are here to resolve any issues that you might be facing and to stay fully committed to supporting you and your crew throughout these challenging times.