VESSEL DETAILS

Name : CMA CGM Rossini

Type: Container Ship

Construction year : 2004

IMO: 9280639

Carrying Capacity: 5782TEU

LOA: 277.28 m

Width: 40m

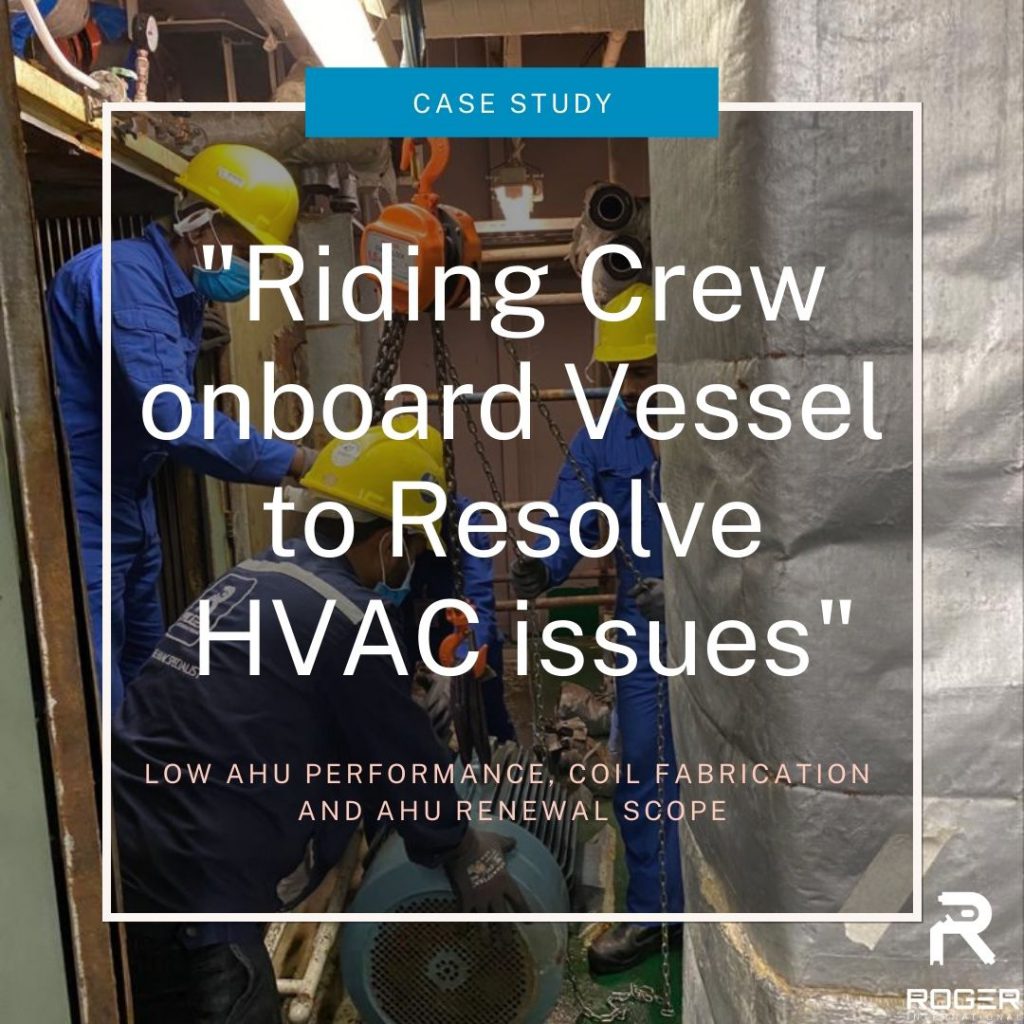

Service Location: Riding Crew, Australia

As per OUR 5-STEPS FORMULATION..

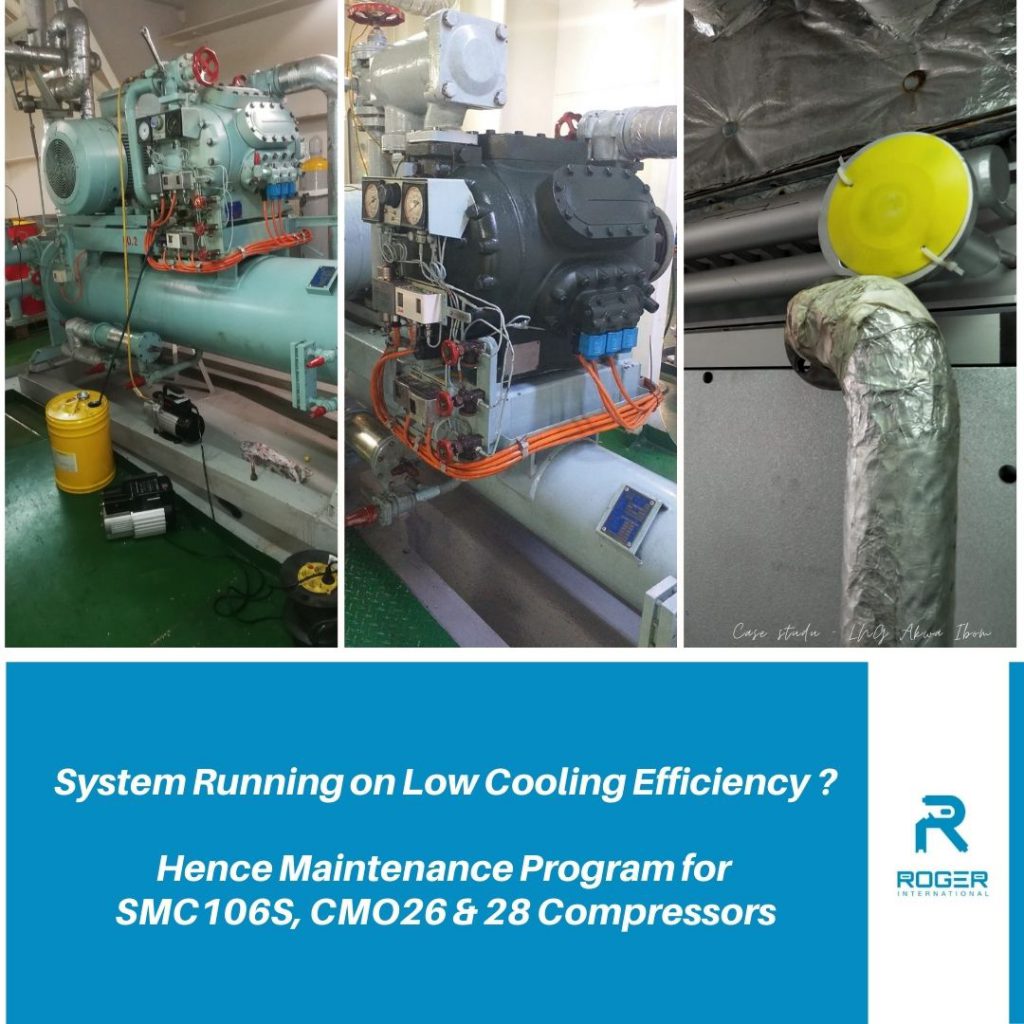

The Problems & Concerns;

- Poor HVAC performance

- AC Maintenance Service

- Worn Parts Removal

- Valves & Flanges Renewal

- Commission of System

The Findings & Solution:

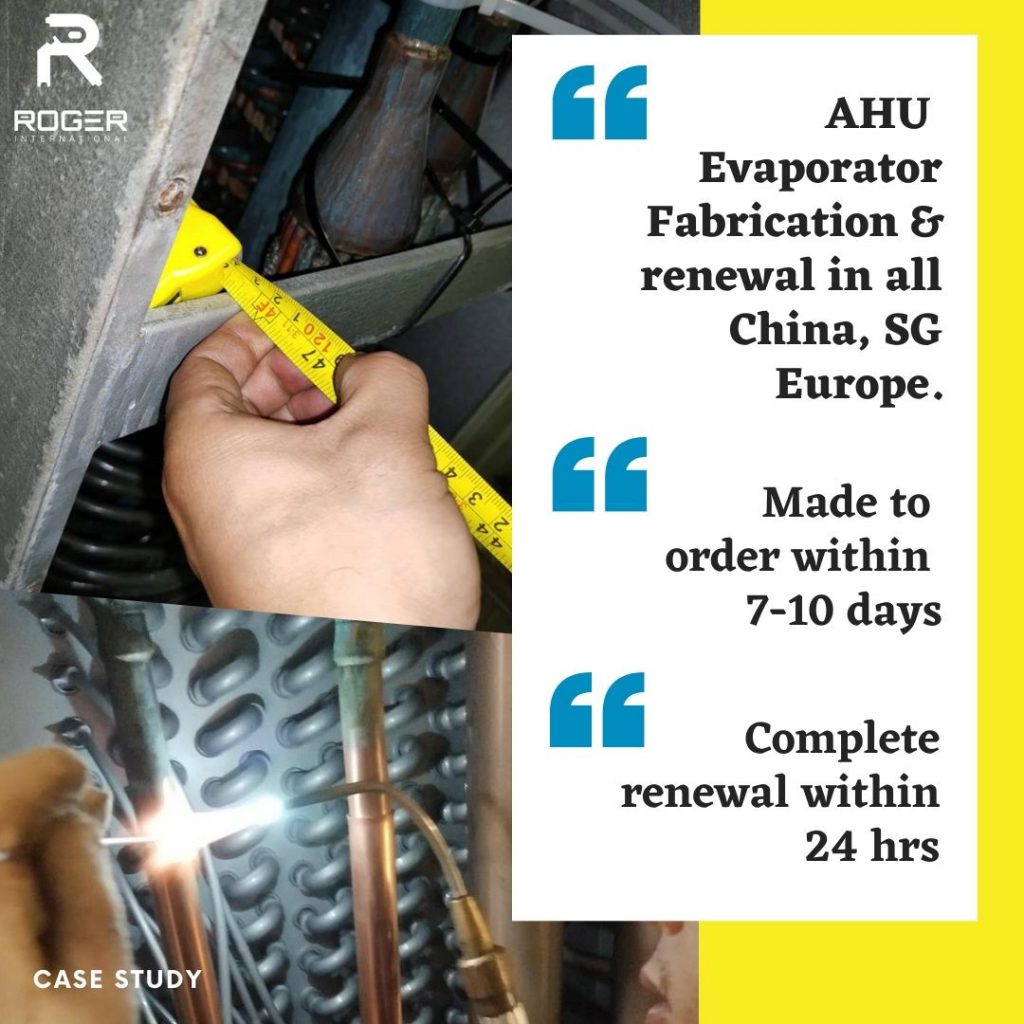

Suction and stop valves were changed with adequate ones and flushing of the system was also done to remove all contaminant deposits that have formed in the unit.

Filter cores were renewed and several hours of leakage tests were conducted. No leaks were found and the units were deemed functional.

The whole process was completed by our Riding Crew in Australia.

The scenario..

Our services were required due to defective Main AC compressor Valves. As per our 5 steps flow set up, we first identified the problem which was simply signs of wear on the units valves. Hence, we proposed our spare parts supplying and replacement services. After defining the damaged items, our experts precisely selected a set of spare parts.

Suction and stop valves were changed with adequate ones and flushing of the system was also done to remove all contaminant deposits that have formed in the unit. As part of our working process and in order to ensure a long lasting optimal performance, filter cores were renewed and several hours of leakage tests were conducted.

No leaks were found and the units were deemed functional. This was a Riding Crew type operation which was conducted in the Adelaide and Fremantle ports which are separated by 3.000 kms.

featuring our riding crew in australia

conducting hvac services onboard the vessel

what you need to know

As you know, Roger International has considerable experience in the maintenance, repair & installation of heating, ventilation and air conditioning systems on board ships.

riding crew conducting hvac services

In this case study, all the operations were performed by our team of technicians and engineers as riding crew. Because flexibility and time are important to our clients, we will adapt to all your constraints and fulfill our mission accordingly.

We are not only able to serve ports, anchorages and shipyards in China, Singapore and Europe, but we are also able to operate as riding crews all over the world.

P.S. : Note that all our engineers are tested and covid free during this pandemic period.

what you need to know about

Suction Valves & Pipes

suction valves & PIPES

Your valves and pipes are under constant pressure. Bad installation works will lead to leaks and early damage. At Roger International, we take all parameters into account in order to offer you long-lasting equipement. As such, pipes and valves are always thoroughly inspected and tested after all our brazing, replacement, cleaning and installation operations.

Flanges

Flanges play a critical role in fluid circulation and need regular service since they are more likely to suffer from leaks than any other equipment. Trust Roger International for the installation, maintenance and replacement of your flanges, thus enabling systems to run under optimal conditions.

P.S. : Note that all our workers are tested and covid free.

similar cases:

Want to find out more about the services involved in this Case Study?

For more information on the process of the services involved, click on the button below to download our FREE Case Study PDF version.

DOWNLOAD THIS CASE STUDY PDF VERSION HERE FOR FREE

RELATED BLOG ARTICLES

BOOK NOW FOR A FREE INSPECTION + GET 10% OFF OUR SERVICES

To eligible for a FREE inspection, all you have to do is to fill up the form below today.

Should u require any parts change or repair works done, we are pleased to inform that we will be extending a 10% off to you if you use the form below.

We are here to resolve any issues that you might be facing and to stay fully committed to supporting you and your crew throughout these challenging times.