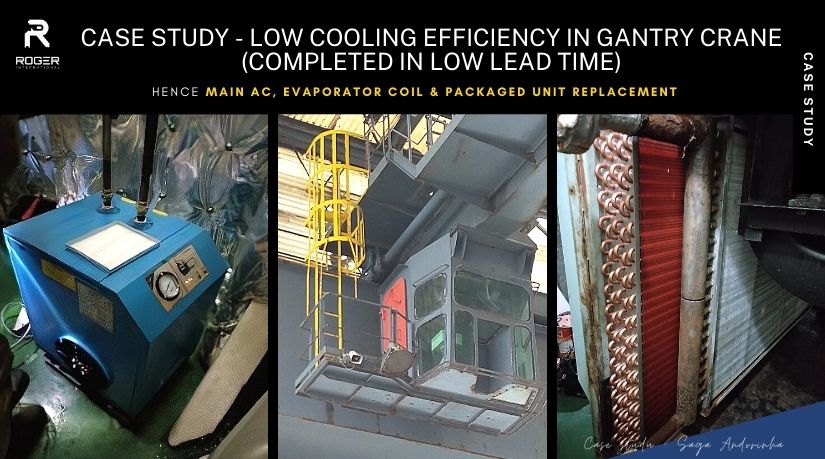

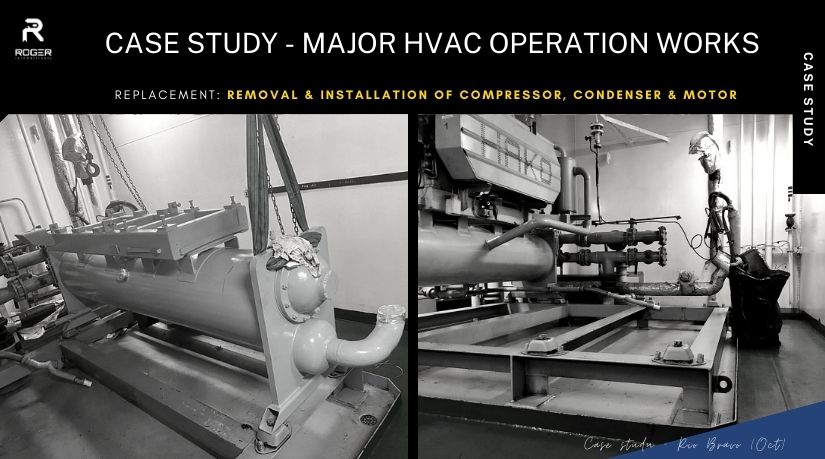

It was found that the vessel suffered from overall low HVAC performance which was due to the PLC malfunctioning, causing system unable to perform due to electronic based.

The provided solution was that we will be able to resolve PLC malfunction error as well as refurbished and retrofitted for both Main AC system through overhauling.